-

Condensate Water Recovery Device

-

Reverse Osmosis Equipment

-

Fully Automatic Water Softener

-

Industrial Sand Filter

-

Water Supply Equipment

-

Chemical Dosing Device

-

Container Flipper

-

Container Loading and Unloading Machine

-

Truck Flipper

-

Electric Transfer Cart

-

Electronic Weighbridge

-

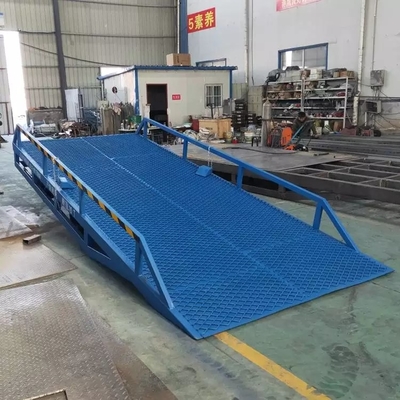

Mobile Loading Dock Ramp

-

Air Compressor Heat Recovery

-

Water Treatment Accessories

15 Ton Tonglida Anti Slip Mesh Dock Plate Ramp With Steel Main Frame

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Features | Customizable According To Specific Requirements | Platform Material | 8mm Anti-slip Mesh For The Platform |

|---|---|---|---|

| Working Platform Size | Between 2 Meters To 4 Meters | Brand | Tonglida |

| Load Capacity | Between 5 To 15 Tons | Origin | Taian, Shandong |

| Main Frame | Made Of Specially Designed Shaped Steel Pipes | Lifting Height | Between 1.2 Meters To 1.8 Meters |

| Highlight | anti slip dock plate ramp,anti slip mobile dock ramp,8mm dock plate ramp |

||

Product Description:

The mobile boarding bridge is constructed using specially designed shaped steel pipes, making it both durable and reliable. Along with this, the platform is equipped with a special diamond-shaped mesh anti-slip plate, ensuring safe operation in all weather conditions.

Its corrugated steel grid structure ensures excellent anti-slip performance, providing better climbing ability and maneuverability for forklifts. This means that regardless of the size and weight of the goods being loaded and unloaded, the mobile boarding bridge can easily and safely handle the task.

Additionally, it is equipped with brake pads to effectively prevent the hydraulic boarding bridge from shifting during truck loading and unloading. The adjustable length chain can easily hook onto the truck, ensuring a tight fit between the boarding bridge and the truck at all times.

With this equipment, forklifts can directly enter the interior of vehicles for batch loading and unloading operations. It requires only one operator and does not require a power source, enabling safe and fast loading and unloading of goods.

In summary, the mobile boarding bridge is an efficient and reliable solution for loading and unloading goods. It not only reduces labor intensity but also greatly improves loading and unloading efficiency, accelerates material flow, and brings greater economic benefits.

Features:

The original text:

With this equipment, forklifts can directly enter the interior of vehicles for batch loading and unloading operations. It requires only one operator and does not require a power source, enabling safe and fast loading and unloading of goods.

The revised text:

The use of this equipment facilitates the entry of forklifts inside vehicles' interiors for batch loading and unloading. The process needs only one operator, without the requirement of a power supply, allowing for safe and swift goods handling.

Technical Parameters:

The platform is constructed with specially designed diamond-patterned mesh plates, ensuring that it maintains reliable strength and is suitable for long-term use without deformation. The diamond-shaped structure of the mesh provides excellent anti-slip performance, which is especially useful for environments where forklifts need to climb and maneuver. The platform can also operate effectively in rainy or snowy weather.

The chain's adjustable length enables easy hooking onto a truck, which guarantees a tight fit between the mobile boarding bridge and the truck at all times. This ensures maximum safety and minimal risk of accidents.

The mobile boarding bridge is powered by a manual hydraulic pump, which eliminates the need for external power sources. This makes it easy to adjust the height of the bridge to match the height of the dock or truck bed, allowing seamless and efficient loading and unloading operations.

The mobile boarding bridge is equipped with brake pads that effectively prevent the bridge from moving during loading and unloading operations. This ensures the safety of workers and cargo by reducing the risk of accidents and mishaps.

Applications:

Mobile boarding bridges play a vital role in many industries, such as warehousing and logistics. These devices are commonly used in facilities like warehouses and distribution centers, making it easier and more efficient to transport goods from the ground to shelves or containers. By enabling swift and efficient loading, unloading, and stacking of goods, mobile boarding bridges help improve workflow and the overall logistics process.

The manufacturing industry also benefits greatly from the use of mobile boarding bridges. They are often used for material transfer between production lines and also help in moving raw materials and finished products from the production line to warehouses or transportation vehicles. This not only reduces labor costs but also helps improve production efficiency and ensure a smooth workflow.

Mobile boarding bridges are also commonly employed in transportation hubs, such as airports, ports, and railway stations. They facilitate faster cargo handling, enhance transportation efficiency, and ensure the safety of goods. By providing an efficient way to transfer goods from the ground to trucks, containers, or airplanes, mobile boarding bridges play an important role in the transportation industry.

Industries with stringent requirements for hygiene and safety, such as food and beverage, pharmaceutical manufacturing, and electronic component production, also rely on mobile boarding bridges. These efficient and secure goods transfer equipment are widely used in production assembly lines within these industries and help ensure a safe and hygienic production environment.